Introduction

When you think of bricks, you think of the iconic red bricks used to construct buildings and commercial structures. However, there are many additional sorts of bricks present.

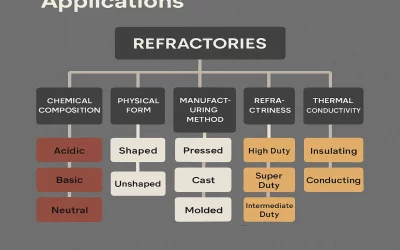

Firebricks, also known as refractory fire bricks, are unique bricks to endure extremely high temperatures. We often use them in high-temperature applications. For example, we frequently found them lining the floors and walls of kilns, furnaces, and ovens.

Buying fire bricks can be a little perplexing. We can pick from a variety of options, and it is difficult to choose which bricks are the right fit for your specific purpose. But Ganesha is a top refractory Fire Brick Manufacturers in India. We will help you solve your confusion and offer you the best decisions as per your needs.

What exactly is fire brick?

A fire brick, also known as refractory fire bricks, is a chunk of ceramic material. We can use this for line burners, kilns, fireboxes, and stoves. They designed a refractory brick to resist high temperatures while still having a poor heat capacity for increased energy efficiency.

They typically employ thick firebricks in conditions requiring high mechanical, toxicological, or thermal pressures. Just like the interior of a wood-fired kiln or burner.

More transparent bricks, known as “kiln bricks,” are preferable in less demanding circumstances, such as an electrical or natural gas-fired kiln. They are less strong, but they are lightweight and quick to make. It insulates significantly better than solid bricks.

How do Soft fire bricks & Hard fire bricks differ?

source : smarthousecolony

Soft fire bricks

Weight – Soft fire bricks are incredibly light and porous. They are not always lighter in weight as compared to hard fire bricks, but they are also much easier to break. In reality, simple tools and equipment can cut them.

The creation of soft fire bricks – Soft fire bricks is created using a unique sort of clay that contains flammable elements and incorporates a foaming agent into a castable refractory formulation.

How it reacts when burned – When burnt, the flammable ingredients burned out of the soft bricks, exposing tiny pockets of air within. Because of these air spaces, the bricks are a suitable alternative for situations requiring extensive insulation.

Where is it found? – Soft fire bricks are most commonly found underneath electric kilns or ovens.

Hard firebricks

Weight – Hard fire bricks are substantially stronger than soft fire bricks. They are also exceptionally long-lasting because they’re much sturdier than soft fire bricks.

Creation of hard fire bricks – We create hard fire bricks using high heat resistant cast refractory formulations. It is formed mostly of alumina and silica and can tolerate extreme temps.

Requirements of hard bricks – It requires a lot of fuel to warm solid brick, and once it’s hot, it reradiated the radiation and maintained the heat more evenly.

Commonly used – We often use Hard brick in corporate furnaces/forges since they don’t have to worry about fuel costs, only about the speed and efficiency of a heated forge all the while. They typically use it in applications requiring a lot of supporting structure.

How is it used? – These bricks are frequently used to construct the outer walls of big ovens or kilns. They are particularly prevalent in applications where we can constantly expose them to open flames.

Insulation – Ovens or kilns made up from hard fire brick tend to heat up more slowly than soft fire brick ovens or kilns because the hard bricks do not provide as much insulation.

Wrapping up

I hope this clarifies the distinction between soft fire bricks and hard fire bricks. When selecting bricks for a high-heat application, you should contact a professional like Ganesha’s.

As leading Refractory Fire Brick Manufacturers in India, we can guide you thoroughly, which results in structured building shape and sturdy construction. And your confusion about which type of refractory fire bricks to choose also solves.